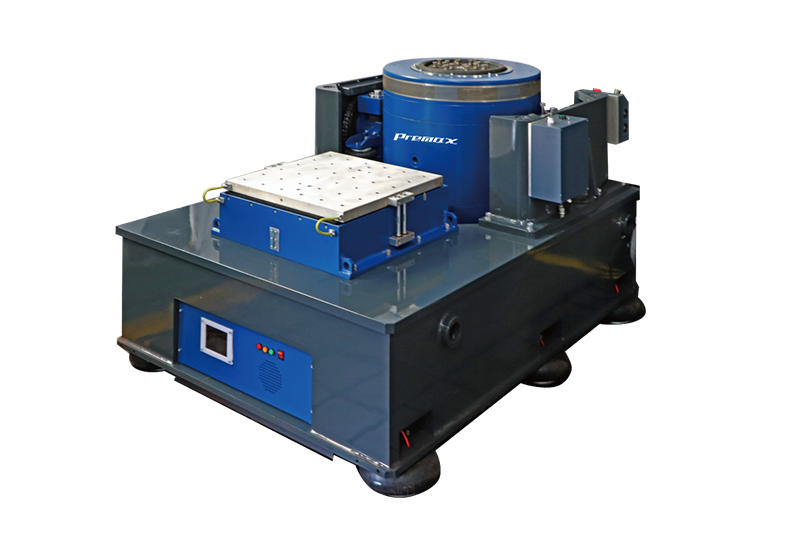

ED shaker

ITS series vibration test systems play an essential role in environmental testing. They provide a testing platform for product vibration testing in various scenarios, such as design and type tests, packaging and transportation assessments, reliability mission profiles, fatigue tests, and more real-world environmental simulations. These tests are crucial across many industries, including automotive, IT, household electrical appliances, satellite, and civil to defense laboratories.

With the VT-9008 series vibration controllers, these vibration testing systems can accurately reproduce realistic vibration conditions for products in the electronics, automotive, aerospace, and aviation industries.

For closed-loop systems, the controller uses displacement, velocity, acceleration, or force as feedback control parameters to simulate a variety of conditions precisely. This capability helps enhance the quality and reliability of products across various sectors.

Applications

Vibration test systems cover a wide range of force outputs from 3kN to 200kN, enabling the testing of tiny objects to large specimens and payloads. Major applications of these systems include:

- Environmental Stress Screening (ESS)

- Packaging and transportation tests

- Road simulation tests for vehicles and components

- Seismic simulation tests

- Other vibration and shock tests

Transportation Vibration Test

The reliability of packaging during transportation is crucial to ensure that the internal goods remain in good condition. Packaging box manufacturers adhere to global reliability verification standards. For instance, the transportation segment of the ISTA 3A standard requires equipment capable of producing large displacements and handling large loads to effectively evaluate the anti-vibration reliability of packaging. In this context, a 32kN vibration shaker is used for packaging and transportation vibration testing.

Features

- Output force from 3kN to 200kN

- Frequency Range: 2 – 4,000 Hz

- Max. Displacement: 3 inches (p-p)

- Max. payload: 2000Kg

- Controller: 8-channel controller with random, sine, Shock, RSTD (Resonance Search and Track Dwell), Sine-on-Random (SoR), Random-on-Random (RoR), Sine and Random on Random (SoRoR), Shock Response Spectrum (SRS), Vibro-Shock Vibration Control, Multisine Vibration Control, etc.

Parameter

|

Model Number |

ITS-300 |

ITS-600 |

ITS-1000 |

ITS-2000 |

ITS-3200 |

ITS-5000 |

ITS-8000 |

ITS-10000 |

ITS-20000 |

|

Max. Sine Force |

3kN |

6kN |

10kN |

20kN |

32kN |

50kN |

80kN |

100kN |

200kN |

|

Frequency Range (Hz) |

5-4000 |

5-3500 |

5-3000 |

5-3000 |

5-2500 |

5-2500 |

5-2500 |

5-2500 |

2-2100 |

|

Max. Displacement (p-p) |

25.4mm/1'' |

51mm/2'' |

51mm/2'' |

51mm/2'' |

51mm/2'' |

51mm/2'' |

76mm/2'' |

76mm/2'' |

76mm/2'' |

|

Max. Velocity |

1.8m/s |

1.8m/s |

1.8m/s |

1.8m/s |

1.8m/s |

1.8m/s |

1.8m/s |

1.8m/s |

1.8m/s |

|

Max. Acceleration(m/s2) |

981 |

981 |

981 |

981 |

981 |

981 |

981 |

981 |

981 |

|

Effective Armature Mass |

3kg/6.6lbs |

6kg/13.2lbs |

10kg/22lbs |

20kg/44lbs |

32kg/71lbs |

50kg/110lbs |

80kg/176lbs |

85kg/187lbs |

180kg/220lbs |