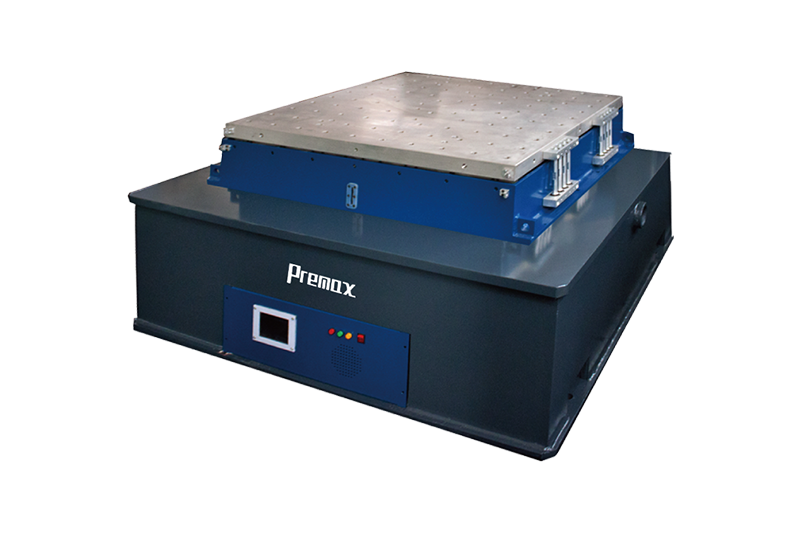

Horizontal Slip Tables

Premax slip tables are meticulously engineered to deliver optimal performance for horizontal testing in conjunction with any shaker system. These tables are oil-lubricated by a continuous oil pressure system, ensuring maximum operational efficiency and extending the lifespan of the equipment.

Slip plates are available in various sizes, ranging from 300mm square for smaller shakers to 1m square for larger specimens. This versatility allows them to meet diverse application requirements and accommodate different operating budgets.

The primary axis of a shaker’s operation is the Z-axis. To achieve vibrations along the X and Y axes, a Horizontal Slip Table is employed. These tables are compactly constructed with a precisely machined magnesium alloy tool plate. The test object can be easily rotated by 90° on the table, allowing for quick and efficient switching between the X and Y axes. When integrated with Premax systems, these slip tables enable comprehensive three-axis testing, and can be paired with temperature and humidity chambers to create an integrated environmental testing system. The area and thickness of the sliding plate are critical factors that determine the system's dynamic performance and affect the table's upper frequency limit.

The selection of a slip table should be based on the specimen's dimensions, required load capacity, maximum anti-overturning moment, and specific testing conditions. In addition to the listed models, custom configurations are available to meet unique customer requirements.

Features

- Optimal Rigidity and Strength: Engineered for superior stiffness and durability, ensuring reliable performance under high-stress conditions.

- Lightweight Magnesium Slip Table: Provides high performance with reduced weight, enhancing system dynamics.

- Economical Aluminum Slip Table Option: Offers a cost-effective alternative without compromising on quality.

- Stiffened and Welded Steel Body: Designed with high mass-to-force ratios to enhance stability and precision.

- Combined Environmental Applications: Seamlessly integrates with environmental test chambers for comprehensive testing.

- Standalone Slip Table: Compatible with both existing and new shaker systems, offering flexibility and adaptability.