Options & Accessories

Options

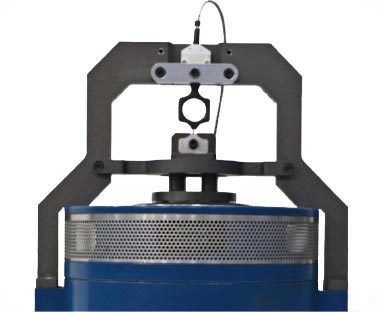

Automatic Centering Controller

The automatic centering system utilizes a non-contact, high-resolution displacement sensor and a PID+fuzzy closed-loop control algorithm to achieve precise automatic centering of the vibration table’s zero position in both static and dynamic conditions. The dynamic centering accuracy can reach within ±1 mm.

Features

- Ease of Operation:

Simple to operate and user-friendly. - Interlocked Emergency Stop Switch:

Ensures safety and reliability. - Static Adjustment:

Automatically adjusts the center position in static conditions. - Dynamic Stability:

Maintains the armature’s central position during dynamic motion.

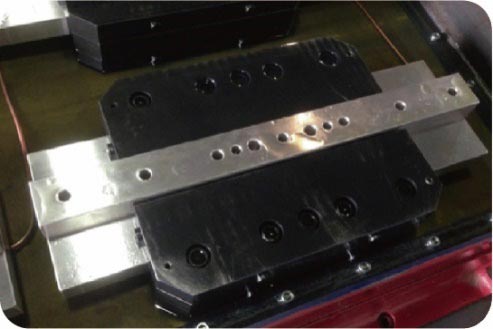

Assembly Fixture

Fixture can assist customers in fixing different Test targets on the shaker to complete Test. Fixtures can be customized according to customer needs.

Features

- High Precision:

Ensures accurate positioning of components during assembly, minimizing errors and improving precision. - Repeatability:

Designed to provide consistent and stable performance, allowing repeated use with identical assembly results. - Custom Design:

Typically tailored to specific product structures and assembly requirements, accommodating unique shapes or functions. - Efficiency:

Reduces assembly time and optimizes workflow, increasing overall production efficiency.

Auxiliary Stay Bearing

Auxiliary support and guidance devices enhance head expander load capacity and offset load resistance. Premax Technologies offers solutions for reliable large-specimen testing while protecting the vibration shaker’s suspension system.

Features

- Precision Machined Surface:

Ensures a uniform and smooth table surface. - Lightweight Materials:

Magnesium alloy available for applications with strict total moving mass requirements. - Thermal Compatibility:

Can be used with insulating pads and temperature control chambers. - System Compatibility:

Designed to integrate seamlessly with the customer's existing vibration shaker system.

Air Spring Isolator

The foundation-free vibration isolation system is ideal for situations where it is inconvenient or challenging to construct a foundation at the customer's site. High-quality air springs elastically support the entire vibration shaker, effectively reducing the shaker's excitation impact on the ground.

Features

- Simplified Installation:

Eliminates the need for complex foundation construction. - Excellent Vibration Isolation:

Provides superior isolation performance. - Portability:

Facilitates easy relocation and mobility of the equipment.

The slip table extends the capabilities of the electrodynamic vibration shaker, enabling three-axis vibration testing. It can also be integrated with temperature and humidity chambers to form a combined environmental testing system. The ST Series Slip Table is compatible with any vibration shaker, providing an optimal testing platform for horizontal testing. Designed and manufactured based on an integrated concept, the steel structure base offers a robust foundation for calibrating both the electrodynamic vibration shaker and the slip table. All slip tables are constructed using precision-machined natural granite and high-quality guide bearings to meet diverse application requirements. The reinforced welded base features excellent reaction force and damping performance, while the built-in vibration isolation system minimizes vibrations transmitted to the ground, preventing interference between testing equipment. Depending on specific application needs, "V-Guide Bearing" and "T-Guide Bearing" options are available.

V-Guide Bearing

The V-Guide Slip Table consists of a horizontal tabletop, V-guide rails, a head expander, a granite slab, a slip table base, and a built-in low-pressure oil source. Equipped with an internal oil pump, it features a compact structure and convenient operation. The number of V-guides varies based on the size of the slip table. This type of V-guide rail offers excellent anti-overturning capability.

T-Guide Bearing

The T-Guide Slip Table consists of a horizontal tabletop, T-guide rails, a head expander, a slip table base, and an independent medium-pressure oil source. T-guide rails deliver exceptional dynamic performance, with each bearing equipped with its own feedback system, ensuring excellent parallel operation capabilities. The design allows for straightforward assembly while maintaining high performance standards. Optional mobility solutions for the table include rail-guided movement or air flotation movement.